Electrodialysis desalination technology

Electrodialysis desalination technology Specification

- pH Range Tolerated

- 6 - 9

- Control System

- PLC-Based Advanced Control

- Temperature Range

- 5°C - 45°C

- Technology Type

- Electrodialysis Desalination

- Suitable For

- Industrial and Municipal Applications

- Automation Grade

- Automatic

- Pretreatment Requirement

- Yes

- Water Source

- Brackish Water/Seawater

- Membrane Type

- Ion Exchange Membrane

- Application Areas

- Water Recycling, Boiler Feed, Textile Industries, Pharmaceuticals

- Operation Mode

- Continuous / Batch

- Minimum Feed TDS

- Up to 20,000 ppm

- Installation Service

- Available

- Skid Mounted

- Yes

Electrodialysis desalination technology Trade Information

- Payment Terms

- Telegraphic Transfer (T/T), Letter of Credit (L/C)

- Sample Available

- No

- Main Export Market(s)

- Central America, Asia, Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Electrodialysis desalination technology

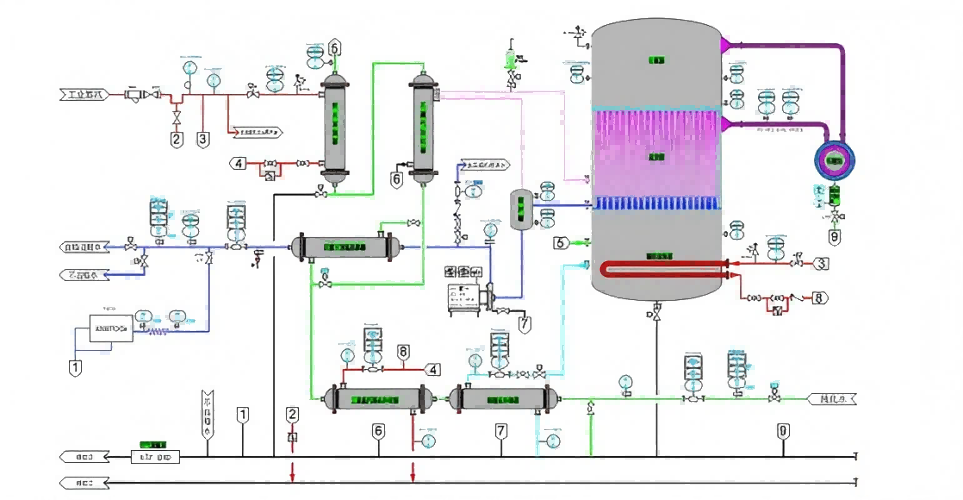

Electrodriven membrane separation equipment is a physical and chemical process that migrates ions from one part of water to another part of water by using the selective permeability of electrodriven membrane under the action of external direct current electric field. The electrodriven membrane separation desalinator uses the electrodialysis process in the multi-layer compartment to achieve the purpose of desalting water.

The electric driven membrane separator consists of a separator, an electric driven membrane, an electrode, a clamping device and other main components. The electrically driven membrane has selective permeability to ions with different charges. The positive film only allows the passage of cations and prevents the passage of anions. The negative film only allows anions to pass through, preventing the passage of cations. Under the action of the external direct current electric field, the ions in water are transferred in a directional manner. Because the electrodriven membrane separator is composed of multi-layer compartments, the anions and ions in the light chamber migrate to the adjacent concentration chamber, so that the brine is desalted.

As a pre-desalting equipment, the electric driven separator can be applied to raw water with salt content of 500-4000mg/L, which has strong practicability and economy. Single water production 0.2-16T/H, desalting rate 75-97%. Widely used in chemical industry, metallurgy, food, biology, pharmaceutical industrial sewage treatment and other fields.

Precision Desalination with Advanced PLC Control

The system emphasizes reliable purification by integrating a sophisticated PLC-based control mechanism, delivering precise management for industrial-grade desalination. Its automation ensures consistent results while adhering to strict quality standards. The advanced control minimizes human error, optimizes processes, and enhances operational safety.

Versatile Applications for Diverse Industries

Adaptability is a core advantage, with the electrodialysis technology engineered for a variety of sectors including textile, pharmaceutical, water recycling, and boiler feed operations. Tailored for both municipal and industrial demands, the system excels in treating brackish water and seawater, making it indispensable in environments where water quality is paramount.

FAQ's of Electrodialysis desalination technology:

Q: How does electrodialysis desalination technology work?

A: Electrodialysis desalination separates dissolved salts from water using ion exchange membranes and electrical potential. The process channels ions through the membranes, leaving behind desalted water suitable for industrial and municipal applications.Q: What are the benefits of the PLC-based advanced control system in this unit?

A: A PLC-based control system offers automated, precise regulation of process parameters. It enhances reliability, streamlines operations, and minimizes manual intervention, ensuring consistent water quality and improved operational efficiency.Q: When is pretreatment required for electrodialysis desalination?

A: Pretreatment is necessary whenever feed water contains impurities such as suspended solids, organic matter, or scaling agents. These need removal to protect membranes and maintain high system efficiency and longevity.Q: Where can this desalination system be installed?

A: This electrodialysis system is mounted on a skid, allowing flexible installation at industrial sites, municipal facilities, textile factories, pharmaceutical plants, or any location requiring reliable salt removal from brackish or seawater.Q: What is the tolerated feed water specification for this technology?

A: The system accommodates feed water with TDS up to 20,000 ppm, a pH range between 6 and 9, and operational temperatures from 5C to 45C, making it suitable for a wide range of challenging water sources.Q: How is the technology beneficial for water recycling and boiler feed?

A: Electrodialysis provides effective reduction of salinity, producing water that meets strict standards for water recycling and boiler feed, thus improving process efficiency, equipment performance, and environmental sustainability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Water Treatment Technology Category

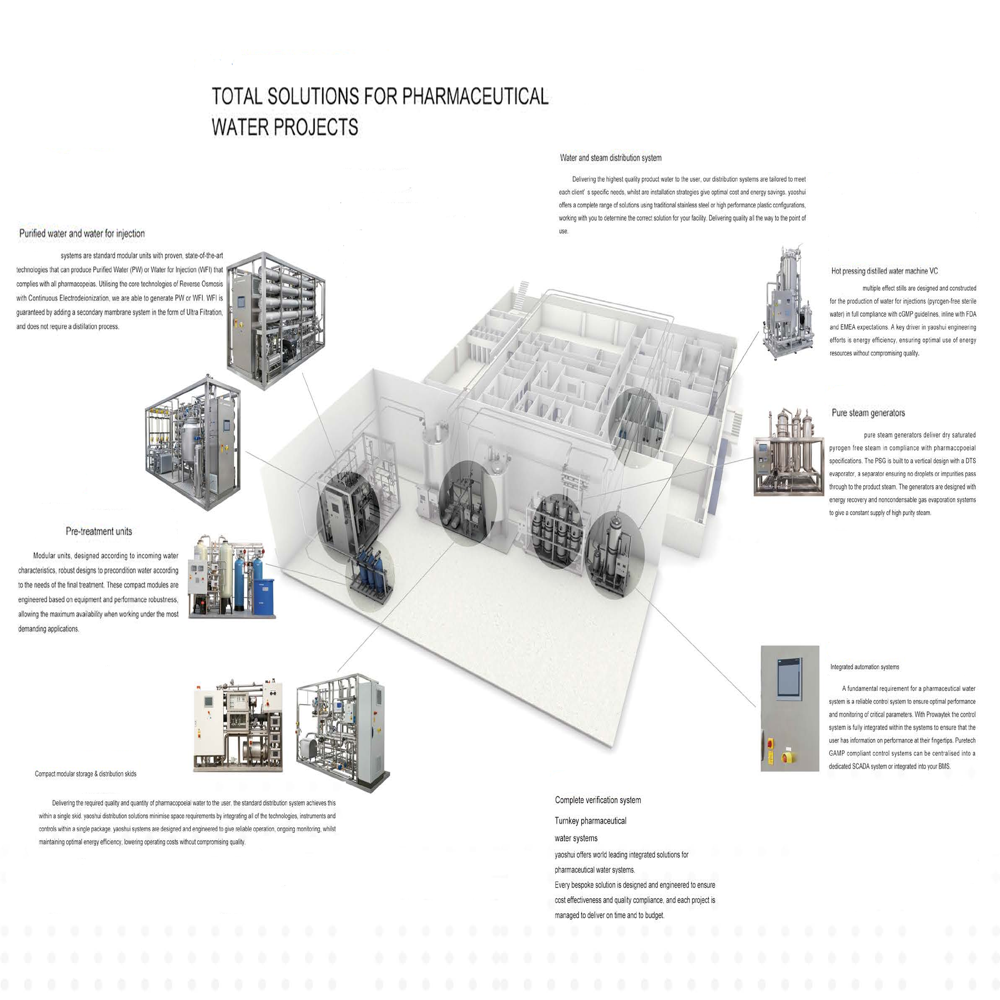

Pharmaceutical use and water integration system

Price 10000.0 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Production process and technology of distilled water and pure water

Price 10000.0 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Diffusion dialysis - waste acid recovery technology

Price 1000.0 USD ($) / Plant

Minimum Order Quantity : 1 Plant

Diffusion dialysis - waste alkali recovery technology

Price 1000.0 USD ($)

Minimum Order Quantity : 1

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry