Production process and technology of distilled water and pure water

Price 10000.0 USD ($)/ Unit

MOQ : 1 Unit

Production process and technology of distilled water and pure water Specification

- Storage

- Sanitary Stainless Steel Tank

- Shelf Life

- Up to 24 months (sealed)

- Filtration Type

- Sand Filtration, Carbon Filtration, Softener, Cartridge Filtration

- Conductivity

- <1 S/cm (distilled); 1-10 S/cm (RO pure)

- Purity Level

- 99.9% (distilled) / Up to 99.5% (RO pure water)

- Color

- Clear, Colorless

- Technology Used

- Reverse Osmosis (RO) and Distillation

- Bacterial Content

- <1 CFU/ml

- Final Treatment

- Distillation, Sterilization

- Packaging Options

- 5L, 10L, 20L cans, custom sizes

- Purification

- Reverse Osmosis

- Product Name

- Distilled Water and Pure Water

- Water Source

- Raw Water (Municipal or well water)

- pH Range

- 5.5 - 7.0

- Application

- Laboratory, Pharmaceutical, Industrial

- Production Process

- Raw water Filters (Sand, Carbon, Softener, Cartridge) Reverse Osmosis (RO) Distillation unit Storage Tank Sterilization

Production process and technology of distilled water and pure water Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Telegraphic Transfer (T/T), Letter of Credit (L/C)

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 2 Months

- Sample Available

- No

- Main Export Market(s)

- North America, South America, Eastern Europe, Asia, Australia, Central America, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Production process and technology of distilled water and pure water

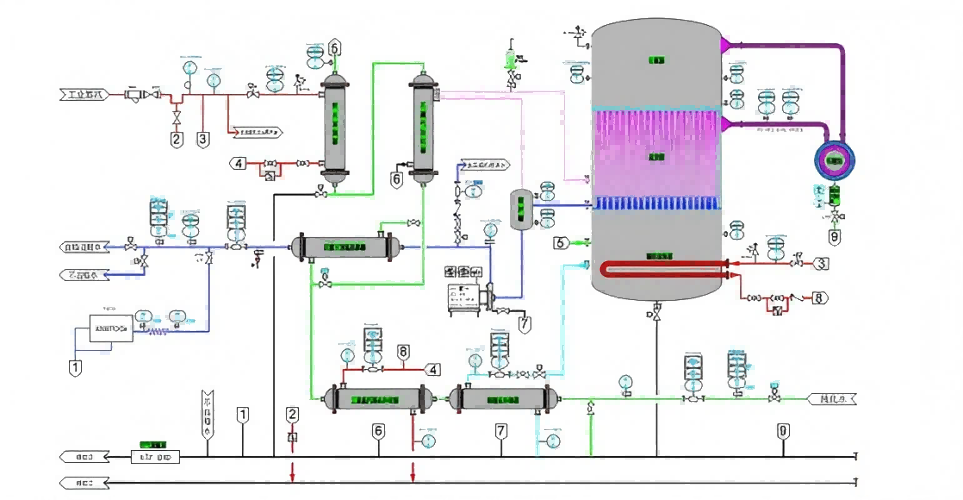

Purified water is heated and evaporated in the tube of a vertical tubular up-film evaporator, and the new steam generated rises and is separated by a high-efficiency vapors and liquids separator. The new steam separated becomes saturated pure steam (also known as dry saturated steam), and the saturated pure steam is pressurized to increase the temperature and enthalpy after being sucked in by the hot compressor, and then sent to the shell of the evaporator by the hot press. The purified water of the pipe is heated and evaporated, and the distilled water itself is condensed into distilled water and flows out of the evaporator, and is sent to the injection water storage tank by the pump for reserve. The purified water that has not been evaporated flows to the bottom from the central pipe of the evaporator, and a small part of it is discharged out of the evaporator as concentrated water and thrown away after cooling, and most of it is mixed with the newly added purified water and then heated to evaporate.

Process description: The purified water is successively sent into the concentrated water cooler, the industrial steam condensate cooler, the distilled water temperature control heat exchanger, the non-condensing gas cooling heat exchanger, and the feedwater heater after heating into the evaporator to be heated and evaporated.

The core technology of hot pressing distilled water machine is to use a steam compressor to pressurize pure steam, thereby increasing the temperature and enthalpy of pure steam, and then using the pure steam after increasing the temperature and enthalpy value to heat and evaporate the purified water in the pipe. The hot press converts electrical energy into compression work, and then converts the compression work into heat energy for evaporation operation, that is to say, electricity is converted into heat energy for evaporation operation to produce distilled water.

The main working energy consumption of the hot press distilled water machine is that the boiler steam is used for heating the material water and the compressor is used for evaporation operation.

Advanced Filtration and Purification

Our production process begins with raw municipal or well water, which passes through sand, carbon, softener, and cartridge filters. This multi-stage filtration effectively removes particulates, organic compounds, hardness, and residual impurities. Reverse osmosis (RO) is then applied to further purify the water, followed by distillation or sterilization, depending on the final desired grade. This meticulous approach ensures stringent purity and safety standards are upheld.

Precise Quality Assurance Measures

We continuously monitor conductivity, pH, and bacterial content at multiple stages, ensuring each batch meets robust industry benchmarks. Advanced instruments assess conductivity to verify it remains below 1 S/cm for distilled water and within 1-10 S/cm for RO pure water. Additionally, our storage tanks are made from sanitary stainless steel, preventing contamination and preserving quality throughout the shelf life.

FAQ's of Production process and technology of distilled water and pure water:

Q: How is distilled water different from pure water produced using reverse osmosis?

A: Distilled water undergoes both reverse osmosis and a final distillation step, resulting in a purity level of 99.9% and extremely low conductivity (<1 S/cm). Pure water produced by reverse osmosis alone achieves up to 99.5% purity and has slightly higher conductivity (1-10 S/cm). Distillation also ensures maximum removal of trace minerals and microorganisms, ideal for sensitive applications.Q: What steps are included in your water purification process?

A: Our process starts with raw municipal or well water filtered using sand, carbon, softener, and cartridge units. It is then purified through reverse osmosis. For distilled water, the product undergoes an additional distillation stage, followed by sterilization before being stored in sanitary stainless steel tanks for final packaging.Q: Where can your distilled and pure water be used?

A: Our high-purity water is suitable for laboratories, pharmaceutical manufacturing, industrial processes, and any application demanding stringent water purity standards. Its minimal bacterial content and controlled conductivity make it ideal for critical testing and production environments.Q: What benefits does your production technology offer compared to basic filtration methods?

A: By combining advanced multi-stage filtration, reverse osmosis, and distillation or sterilization, we achieve exceptionally high purity and reliability. This guarantees the removal of a wide range of impurities, including bacteria and trace ions, far exceeding the capabilities of basic filtration methods and ensuring water meets demanding industry standards.Q: How long does your water remain suitable for use after packaging?

A: Our distilled and pure water maintains stability and quality for up to 24 months when kept in sealed containers. The use of sanitary stainless steel tanks and rigorous sterilization processes minimizes the risk of contamination, supporting a long shelf life.Q: What packaging options are available for your distilled and pure water products?

A: We offer 5L, 10L, 20L cans, and can accommodate custom size requests to best suit your operational needs. All packaging maintains water clarity and quality throughout its shelf life.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Water Treatment Technology Category

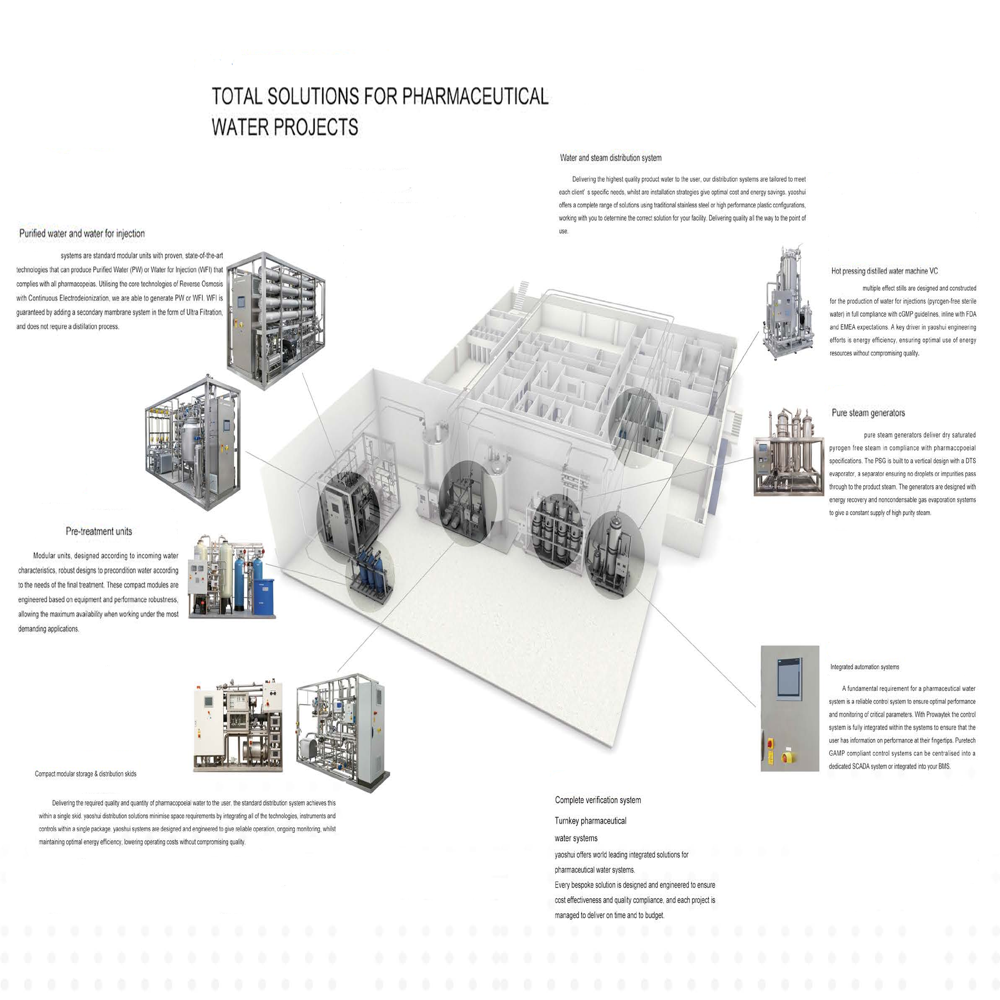

Pharmaceutical use and water integration system

Price 10000.0 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Diffusion dialysis - waste acid recovery technology

Price 1000.0 USD ($) / Plant

Minimum Order Quantity : 1 Plant

Diffusion dialysis - waste alkali recovery technology

Price 1000.0 USD ($)

Minimum Order Quantity : 1

Diffusion dialysis and electrodialysis combined technology

Price 1000.0 USD ($)

Minimum Order Quantity : 1

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Call Me Free

Call Me Free