Diffusion dialysis - waste alkali recovery technology

Diffusion dialysis - waste alkali recovery technology Specification

- Installation Type

- Turnkey/Retrofit

- Service Life of Membrane

- 23 years under standard conditions

- Application

- Recovery of waste alkali (e.g., NaOH) from industrial wastewater

- Membrane Area

- Customizable according to treatment capacity (standard module: 1050 m)

- Membrane Material

- Anion Exchange Membrane

- Alkali Recovery Rate

- Above 70% (depending on feed composition)

- Process Type

- Membrane Separation (Diffusion Dialysis)

- Energy Consumption

- Low no heating required

- Residual Salt Content in Recovered Alkali

- <4% (mass basis)

- Typical Maintenance Interval

- 1218 months membrane replacement

- pH Range for Operation

- 2 to 14

- Pretreatment Requirement

- Simple filtration for particles >5 micron

- Automation Level

- Fully automatic/PLC controlled

- Residual Alkali in Effluent

- <0.02 mol/L (depending on feed concentration)

- Operating Temperature

- Room temperature to 50C

- System Configuration

- Modular, Skid-mounted

- Typical System Capacity

- 10020,000 L/h

- Feed Solution Type

- Alkali-containing industrial wastewater, such as from metal surface treatment, PCB, and electroplating industries

- Product Name

- Diffusion Dialysis - Waste Alkali Recovery Technology

- Advantages

- Reduces caustic loss and wastewater pollution; highly energy-efficient because no external driving force required except concentration difference

Diffusion dialysis - waste alkali recovery technology Trade Information

- Payment Terms

- Telegraphic Transfer (T/T), Letter of Credit (L/C)

- Sample Available

- No

- Main Export Market(s)

- Africa, Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East

- Main Domestic Market

- All India

- Certifications

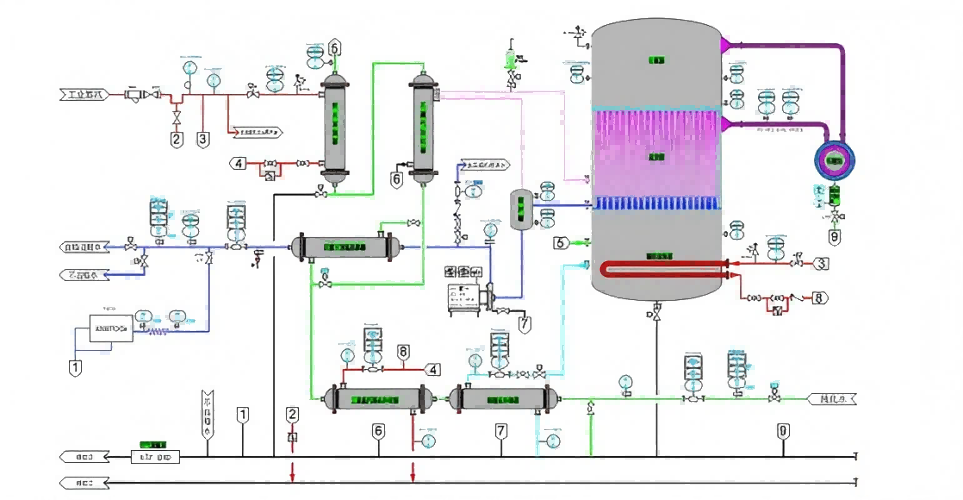

- The whole device is a series of structural units composed of a certain number of membranes. Each unit has a cationic homogeneous membrane separated into a dialysis chamber and a diffusion chamber. Countercurrent operation is adopted. When the waste lye and the receiving liquid (tap water) are passed into both sides of the cationic homogeneous membrane, the concentration of alkali and its salt on the waste lye side is much higher than that on the water side. However, the membrane has selective permeability to cations, so under the effect of the concentration difference, the cations on the waste alkali side are attracted and enter the water side smoothly through the membrane pore channel. At the same time, according to the requirements of electric neutrality, anions are also included, because the hydration radius of OH- is relatively small, and the charge is less. Other anions have a larger hydration radius and more charge, so OH- will preferratively pass through the membrane, so that the alkali in the waste liquid will be separated.

About Diffusion dialysis - waste alkali recovery technology

Diffusion dialysis recovery of waste alkali and recovery of waste acid are the application of dialysis principle, are driven by concentration difference, the difference is that used as diffusion dialysis membrane is not anion exchange membrane but cation exchange membrane. As shown in the figure below, when both sides of the cationic homogeneous membrane pass into the waste lye and the receiving solution (tap water), the concentration of alkali and its salt on the waste lye side is much higher than that on the water side. Therefore, due to the existence of concentration gradient, the waste alkali and its salt have a tendency to penetrate the diffusion chamber. However, the membrane is selective and will not allow each ion to pass through with equal opportunities. First of all, the cation exchange membrane skeleton itself is negatively charged, which has the characteristics of attracting positively charged hydrated ions and repelling negatively charged hydrated ions in solution. Therefore, under the effect of the concentration difference, the cation on the waste alkali side is attracted and smoothly enters the water side through the membrane pore channel. At the same time, according to the requirements of electric neutrality, negatively charged ions will also be included, because the hydration radius of OH- is relatively small, the charge is less; Other anions have larger radii, so OH- will preferentially pass through the membrane, so that the alkali in the waste solution will be separated.

Efficient Alkali Recovery for Industrial Wastewater

This technology ensures recovery rates above 70% for alkali, significantly reducing operational costs and environmental impact. It effectively recycles alkali from wastewater streams, helping industries comply with discharge norms while reclaiming valuable resources. The process operates efficiently at room temperature, maximizing practicality for various industrial settings.

Customizable Modular System

The system features a modular and skid-mounted design, with membrane area adaptable to specific treatment capacities ranging from 100 to 20,000 L/h. Whether for new installations or retrofitting existing ones, it offers flexible configuration and straightforward integration, making it suitable for diverse industrial requirements.

Low Maintenance and Long Service Life

Diffusion Dialysis systems require minimal pretreatment-just filtration for particles above 5 microns-and offer typical membrane lifespans of 2-3 years. Maintenance intervals for membrane replacement are usually 12-18 months, ensuring consistent performance and low downtime. Full automation and PLC control add to its user-friendly operation.

FAQ's of Diffusion dialysis - waste alkali recovery technology:

Q: How does the Diffusion Dialysis - Waste Alkali Recovery Technology operate?

A: This technology employs anion exchange membranes to separate and recover alkali from industrial wastewater. Driven solely by concentration difference, the system does not require external energy inputs like heating or pressure, making it highly energy-efficient.Q: What types of industrial wastewater can be treated using this process?

A: The system is suitable for alkali-containing wastewaters arising from metal surface treatment, PCB, and electroplating industries. It effectively recovers alkali such as sodium hydroxide from these waste streams.Q: When should the membrane be replaced during regular operation?

A: Under standard operating conditions, the system requires membrane replacement every 12 to 18 months to ensure optimal performance. The membrane typically offers a service life of 2 to 3 years.Q: Where can the Diffusion Dialysis system be installed?

A: Installations are available as turnkey solutions or retrofits, making it suitable for both new plants and upgrades to existing facilities across various industrial sectors in India and beyond.Q: What is the typical process involved before diffusion dialysis starts?

A: The only pretreatment required is simple filtration to remove particles larger than 5 microns from the wastewater feed. After this step, the feed solution is processed directly by the membrane system.Q: How is the recovered alkali quality ensured?

A: The recovered alkali generally contains less than 4% residual salt (mass basis), while the residual alkali in treated effluent is typically below 0.02 mol/L. These values depend on the initial feed concentration, ensuring effective and high-quality alkali recovery.Q: What are the primary benefits of using this technology?

A: Key advantages include substantial reduction in caustic losses, decreased environmental pollution from wastewater, and low energy consumption. The fully automated, PLC-controlled modular system also provides operational simplicity and economic value.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Water Treatment Technology Category

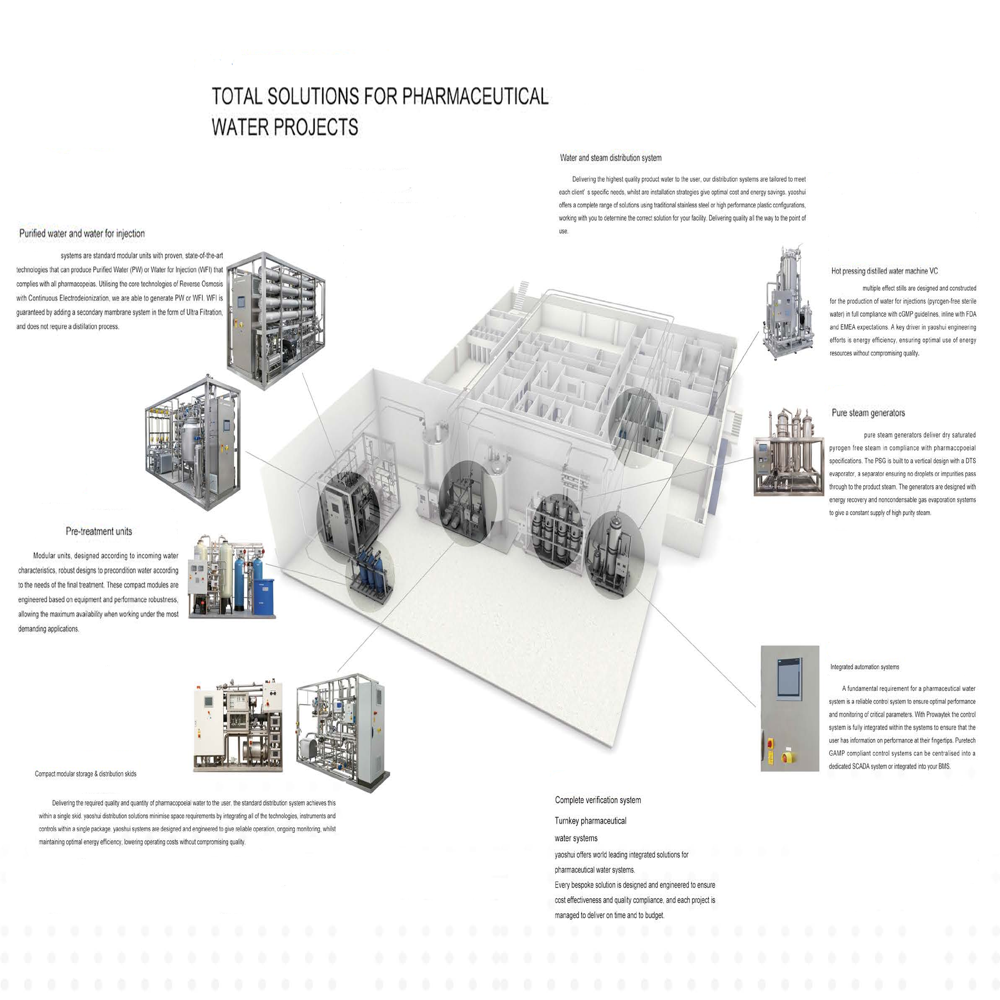

Pharmaceutical use and water integration system

Price 10000.0 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Production process and technology of distilled water and pure water

Price 10000.0 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Diffusion dialysis - waste acid recovery technology

Price 1000.0 USD ($) / Plant

Minimum Order Quantity : 1 Plant

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry