Diffusion dialysis - waste acid recovery technology

Price 1000.0 USD ($)/ Plant

Diffusion dialysis - waste acid recovery technology Specification

- System Footprint

- Compact skid-mounted design

- Recovery Efficiency

- Up to 95% for selected acids under optimal conditions

- Materials of Construction

- Corrosion-resistant plastics and stainless steel

- Maintenance

- Minimal, periodic membrane inspection and cleaning

- Application

- Metallurgy, PCB, electroplating, pickling, and chemical industries

- Separation Principle

- Selectively permeable anion-exchange membrane enabling diffusion of acids and metal ions

- Membrane Type

- Anion exchange membrane

- Automation Level

- PLC controlled with user-friendly HMI

- Product Name

- Diffusion Dialysis - Waste Acid Recovery Technology

- Acid Purity After Recovery

- Typically above 95%

- Acid Types

- Sulphuric acid, hydrochloric acid, nitric acid, and phosphoric acid

- Compliance

- Meets international environmental standards (RoHS/REACH)

- pH Range

- 0-2

- Operation Mode

- Continuous or batch

- Installation

- On-site integration with existing effluent streams

- Operating Temperature

- 10C 50C

- Typical Recovery Rate

- 70-90% (depending on operating conditions and waste composition)

- Function

- Separation and recovery of waste acids from industrial effluents

- Typical Metal Removal

- Up to 95% iron, copper, nickel (varies per stream)

- Membrane Lifetime

- 2-4 years depending on conditions

- Power Requirement

- Less than 0.5 kW/module

- Advantages

- Cost-effective, Eco-friendly, Low energy consumption, Simple operation

- Flow Rate Capacity

- Up to 5 m3/h per module

Diffusion dialysis - waste acid recovery technology Trade Information

- Minimum Order Quantity

- 1 Plant

- Payment Terms

- Telegraphic Transfer (T/T), Letter of Credit (L/C)

- Sample Available

- No

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

- Certifications

- Process advantages: 1, good removal of organic matter in waste acid, special adsorption material adsorption capacity, high concentration ratio, low cost; 2, the waste acid after treatment can be recycled for production, to realize the resource utilization of waste acid; 3, waste acid recovery and treatment equipment covers an area of saving, compact structure, less civil construction and equipment costs, multiple application of desorption agent, step by step enrichment, high utilization rate of agents, low operating costs; 4, can achieve module component form, can be flexibly adjusted according to production capacity, easy to install; 5, waste acid recovery process is good, mature, strong technical support and rich experience in engineering application.

About Diffusion dialysis - waste acid recovery technology

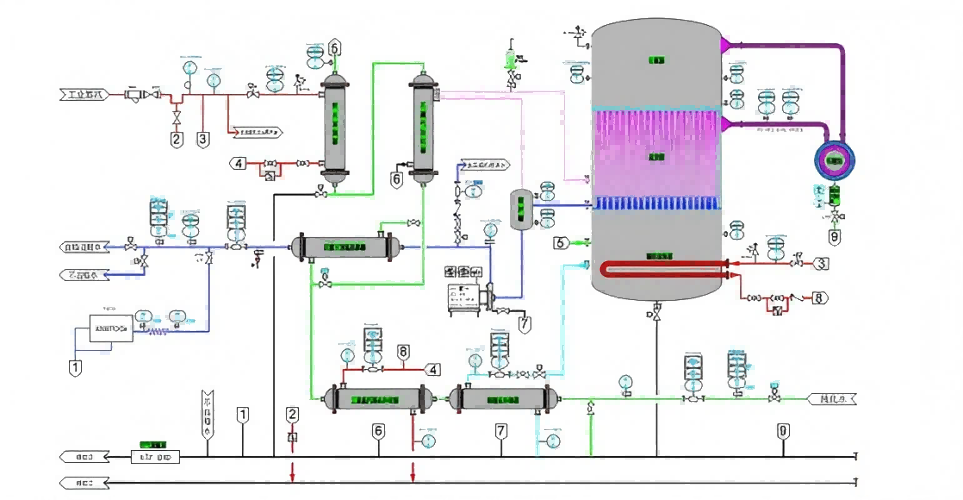

Diffusion dialysis method (ionic membrane method) to recover waste acid adopts the principle of dialysis, which is driven by concentration difference. This product membrane and its equipment are mainly used for the separation and purification of the mixed liquid of acid and metal salts, which is a good choice in the field of waste acid. It has the advantages of simple operation, saving energy and resources, no secondary pollution, etc. The recovered acid can be recycled, and the residual liquid after separating acid can recover useful metals. It is widely used in various fields of discharge of waste acid: such as iron and steel industry, titanium dioxide industry, wet smelting of copper industry, electroplating industry, formation, rare earth industry and other non-ferrous metal smelting industry, the types of recovered acid can include sulfuric acid, hydrochloric acid, HF, nitric acid, etc., the metal ions involved mainly include transition metal ions, rare earth ions and magnesium calcium and so on. The recovery rate of acid can reach more than 80%, and the removal rate of metal ions can reach more than 90%.

Efficient Acid Recovery and Metal Removal

This technology is engineered to recover sulfuric, hydrochloric, nitric, and phosphoric acids from industrial waste streams, achieving up to 95% recovery efficiency under optimal conditions. Additionally, it removes up to 95% of metals such as iron, copper, and nickel, greatly reducing environmental hazards and enabling reclaimed acids to be reused in your process.

Compact and Flexible Installation

With a footprint-friendly, skid-mounted design, the system integrates seamlessly into existing effluent treatment setups. Constructed with corrosion-resistant materials, it supports both continuous and batch operations and can handle flow rates up to 5 m3/h per module, allowing scalable installation according to your facility's needs.

Simple Operation and Minimal Energy Consumption

The system's automated PLC control and user-friendly HMI ensure effortless monitoring and adjustment, while its low power consumption (less than 0.5 kW per module) makes it a cost-effective solution. Routine membrane inspection and periodic cleaning are all that's needed for reliable, long-term performance.

FAQ's of Diffusion dialysis - waste acid recovery technology:

Q: How does diffusion dialysis recover acids from industrial waste streams?

A: Diffusion dialysis utilizes an anion exchange membrane that selectively allows acid molecules and certain metal ions to diffuse through. This process efficiently separates and recovers acids from the waste effluent, while retaining most impurities on the other side of the membrane.Q: What industries commonly use this waste acid recovery technology?

A: This technology is widely used in metallurgy, printed circuit board manufacturing, electroplating, pickling, and other chemical processing industries where significant amounts of acids are utilized and need to be recovered for cost and environmental reasons.Q: When should diffusion dialysis be installed in an effluent treatment process?

A: It is best to install this system on-site, directly integrating it with existing effluent streams that contain recoverable acids and dissolved metals. It can be used either as a continuous treatment or in batch mode, depending on your process requirements and effluent production.Q: Where is the system typically installed, and how compact is it?

A: Thanks to its skid-mounted and space-saving design, the system is usually installed within industrial plants right next to waste acid generation points. Its compact footprint allows for hassle-free integration without significant changes to plant layout.Q: What is the operating process for this waste acid recovery system?

A: The unit operates by pumping waste acid through modules containing anion exchange membranes. Acids pass through the membrane via diffusion, while metal ions are selectively retained or removed, depending on their charge and size. The recovered acid can then be collected and reused.Q: How should the recovered acid be used and what is its typical quality?

A: Recovered acids, with purity typically above 95%, can be reused in various industrial processes such as metal pickling or plating. Their quality is suitable for most applications previously using the original acid, reducing raw material needs and disposal costs.Q: What are the key benefits of using diffusion dialysis in acid recovery?

A: Key advantages include significant cost savings, reduced sludge and environmental impact, high recovery efficiency, low energy consumption, and simplified operation and maintenance. By recovering and reusing acids, companies can comply with environmental regulations while enhancing sustainability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Water Treatment Technology Category

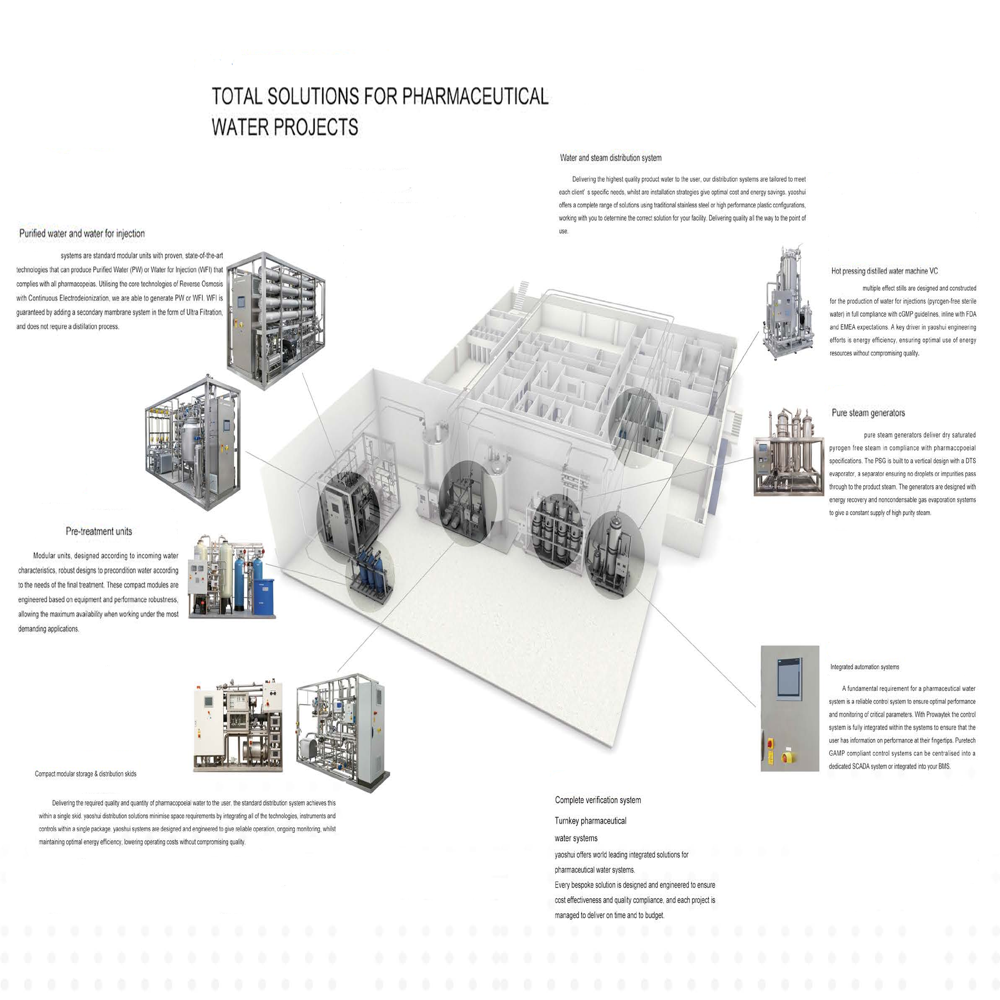

Pharmaceutical use and water integration system

Price 10000.0 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Production process and technology of distilled water and pure water

Price 10000.0 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Diffusion dialysis - waste alkali recovery technology

Price 1000.0 USD ($)

Minimum Order Quantity : 1

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Call Me Free

Call Me Free