Combined technique of nanofiltration and electrodialysis NF-ED

Combined technique of nanofiltration and electrodialysis NF-ED Specification

- Electrode Material (ED)

- Titanium coated with noble metal oxides

- Cleaning Method

- CIP (Clean-in-Place) Supported

- Salt Rejection (NF)

- 60-98%

- Protection

- Overpressure and leak detection included

- Max TDS Input (Feed)

- Up to 30,000 mg/L

- Electrical Consumption (ED)

- 1.5-3.5 kWh/m

- Working Temperature

- 5-45C

- Compliance

- Meets international water quality standards

- Typical Application

- Desalination, Water Softening, Removal of Hardness, Industrial Wastewater Treatment

- Flow Rate Range

- 0.1 100 m/h

- Control System

- PLC-based automatic operation

- Technology

- Nanofiltration (NF) and Electrodialysis (ED) Combined

- Integrated Pretreatment

- Optional automatic filtration unit

- Operation Pressure (NF)

- 5-40 bar

- Product Name

- Combined technique of nanofiltration electrodialysis (NF-ED)

- pH Operating Range

- 3-11

- System Configuration

- Skid Mounted / Modular Design

- Footprint

- Compact, Space-saving layout

- Recovery Rate

- Up to 85%

- Membrane Type

- Polymeric/Composite Membranes

Combined technique of nanofiltration and electrodialysis NF-ED Trade Information

- Payment Terms

- Telegraphic Transfer (T/T), Letter of Credit (L/C)

- Sample Available

- No

- Main Export Market(s)

- Central America, North America, South America, Eastern Europe, Western Europe, Africa, Asia, Australia, Middle East

- Main Domestic Market

- All India

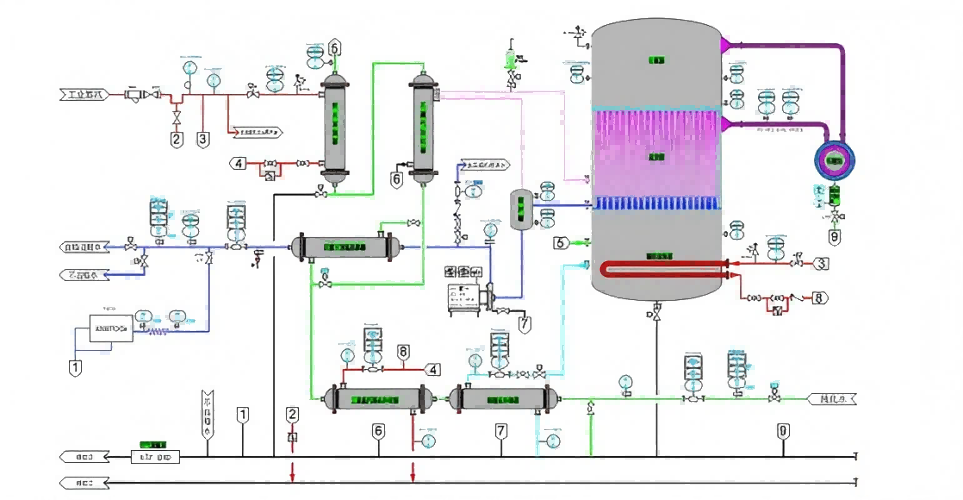

About Combined technique of nanofiltration and electrodialysis NF-ED

Through the combined application of nanofiltration and electrodialysis, the raw materials can be fully utilized, the output of wastewater can be reduced, the cost can be reduced, and the income can be increased.

Step1

Bisglyphosate production wastewater, sodium chloride 22%, formaldehyde 1600 ppm, bisglyphosate -1.2%, total phosphorus 12,000 ppm;

Step2

Nanofiltration for salt separation and simultaneous concentration of bisglyphosate;

Step3

Electrodialysis treatment of nanofiltration concentrate, separating salt from organic matter;

Step4

Nanofiltration brine and electrodialysis brine evaporation and crystallization, organic wastewater concentration and incineration.

Compact, Space-saving Design

The NF-ED system's skid-mounted, modular configuration is engineered to optimize available floor space, making it ideal for facilities with space constraints. Its compact design not only reduces installation footprint but also simplifies integration into existing water treatment processes. This adaptability allows for greater flexibility in deploying advanced water purification technology even in limited or challenging environments.

Versatile Applications and High Performance

The combined NF-ED technology is suitable for a variety of demanding applications including desalination, water softening, removal of hardness, and industrial wastewater treatment. With its ability to process feedwater containing up to 30,000 mg/L TDS and operate within a wide pH range (3-11), it delivers strong salt rejection rates (60-98% via NF) and energy efficiency, thanks to ED's low electrical consumption (1.5-3.5 kWh/m3).

Reliable Operation and Quality Compliance

Featuring an integrated PLC-based automatic control system, overpressure and leak detection, and optional automatic filtration pretreatment, the NF-ED system assures safe, consistent, and user-friendly operation. The system is designed to meet international water quality standards, providing assurance to operators and end-users alike. Periodic maintenance is streamlined with CIP (Clean-in-Place) methods.

FAQ's of Combined technique of nanofiltration and electrodialysis NF-ED:

Q: How does the combined nanofiltration and electrodialysis system (NF-ED) improve water treatment?

A: The NF-ED system enhances water treatment by merging nanofiltration for efficient salt and hardness removal with electrodialysis for ion separation, delivering high-quality, softened water. This combined approach enables high recovery rates (up to 85%) and supports a broad range of input water qualities, up to 30,000 mg/L TDS.Q: What types of applications can the NF-ED system be used for?

A: The NF-ED system is typically applied in industrial desalination, water softening, removal of hardness, and treating industrial wastewater. Its robust design allows it to handle challenging water sources, including those with high salinity and diverse contaminant profiles.Q: When is integrated pretreatment with automatic filtration necessary?

A: Integrated pretreatment with the optional automatic filtration unit is recommended when feedwater contains significant suspended solids or turbidity. This protects the membranes and electrodes, extends system lifespan, and maintains operational efficiency.Q: Where can the NF-ED system be installed, considering its design and footprint?

A: Thanks to its modular, skid-mounted, and compact layout, the NF-ED system can be installed in a wide range of industrial settings, including factories, water treatment plants, and facilities with limited available space. Its space-saving design facilitates easy integration into existing infrastructure.Q: What is the typical recovery rate and how does it benefit operations?

A: The NF-ED system achieves recovery rates of up to 85%, significantly reducing water waste and operational costs. High recovery rates support sustainable use of resources, especially valuable in water-scarce regions or industries focused on environmental efficiency.Q: How does the PLC-based control system contribute to operation and maintenance?

A: The PLC-based automatic control system ensures precise operation, real-time monitoring, and automatic responses to process changes. It simplifies daily management and reduces manual intervention, while features like overpressure and leak detection enhance safety and system integrity.Q: What are the main benefits of using titanium electrodes coated with noble metal oxides in this system?

A: Titanium electrodes coated with noble metal oxides provide superior resistance to corrosion and fouling, enhance longevity, and improve electrical efficiency within the electrodialysis process, contributing to the system's overall reliability and low maintenance requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Water Treatment Technology Category

Production process and technology of distilled water and pure water

Price 10000.0 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Diffusion dialysis - waste acid recovery technology

Price 1000.0 USD ($) / Plant

Minimum Order Quantity : 1 Plant

Diffusion dialysis - waste alkali recovery technology

Price 1000.0 USD ($)

Minimum Order Quantity : 1

Diffusion dialysis and electrodialysis combined technology

Price 1000.0 USD ($)

Minimum Order Quantity : 1

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry