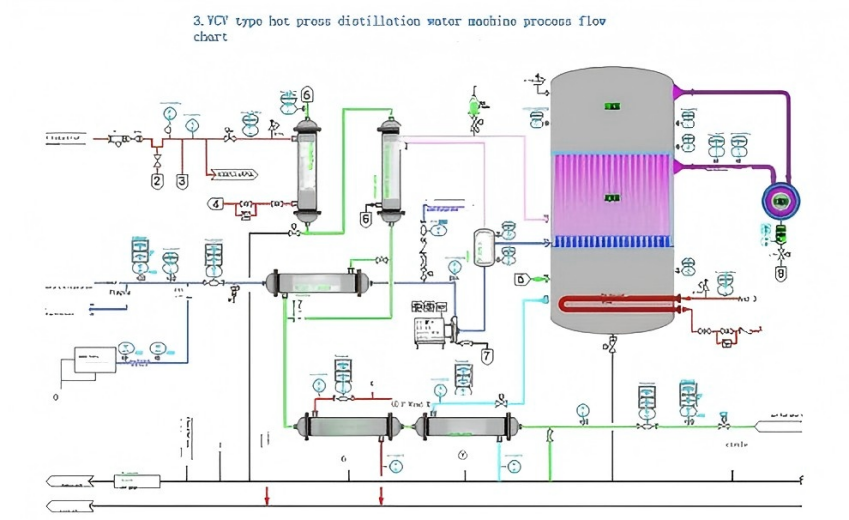

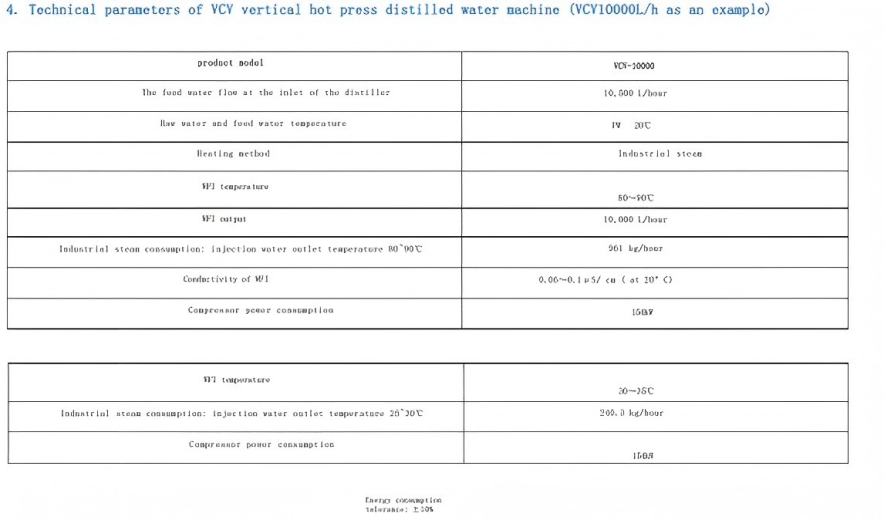

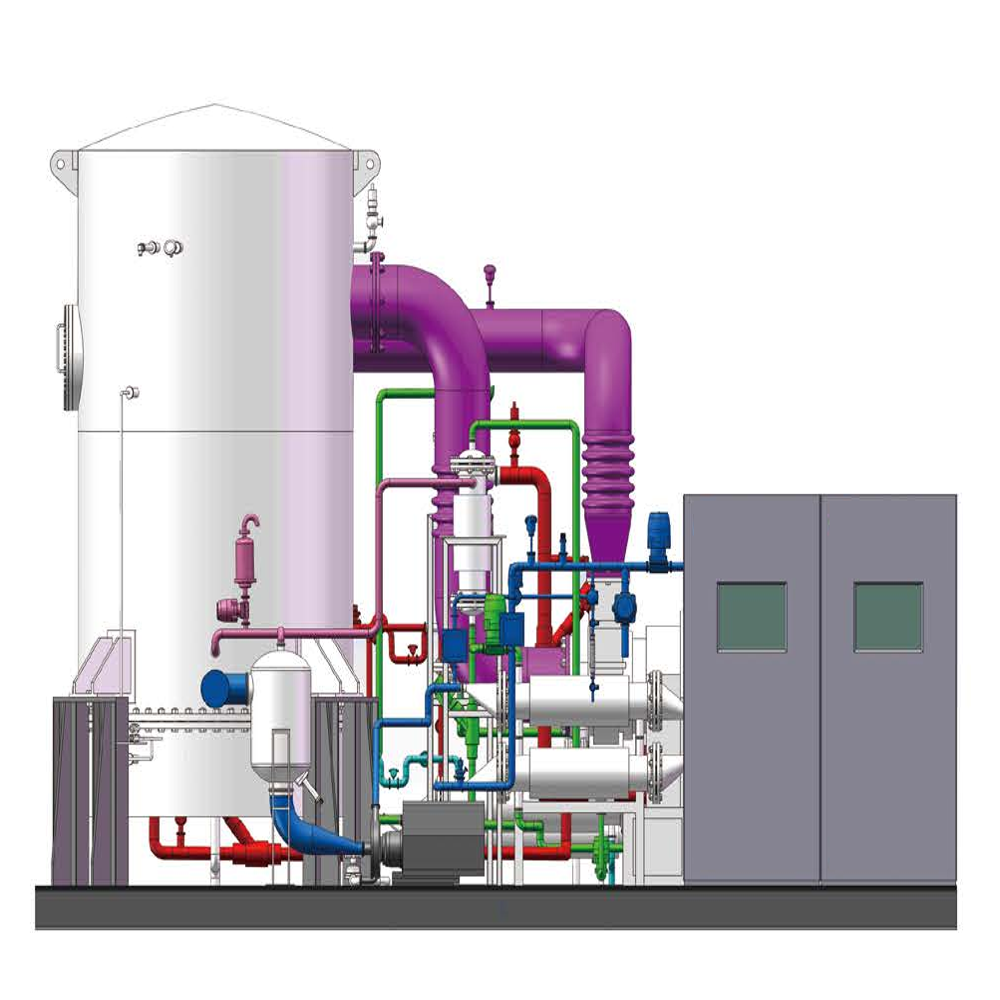

Vertical hot pressure distilled water machine

Price 30000.0 USD ($)/ Unit

Vertical hot pressure distilled water machine Specification

- Water Out Conductivity

- 0.06 0.1 S/cm at 20

- Power Consumption

- 154 Kilowatt (kW)

- Water Source

- Ground Water

- Automatic Grade

- Full Automatic

- Purity Level

- 99.99%H20

- Drive Type

- Electric

Vertical hot pressure distilled water machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Telegraphic Transfer (T/T), Letter of Credit (L/C)

- Supply Ability

- 1 Unit Per Week

- Delivery Time

- 3 Months

- Sample Available

- No

- Main Export Market(s)

- Asia, Australia, South America, Western Europe, Middle East, Africa, Central America, North America, Eastern Europe

- Main Domestic Market

- All India

- Certifications

- FDA\cGMA

About Vertical hot pressure distilled water machine

Long service life: up to 30 years;

Reduce operating and maintenance costs.

The effluent water quality complies with the European Union, the United States, Japan and other international standards;

Industrial steam consumption is low, only about 35% of the multi-efficiency;

Industrial steam pressure requirement is low (only 3 barg or lower);

Wide range of water production temperature: it can produce 3595 of water for injection;

Non-condensate gas removal device can effectively separate the non-condensable gas;

Injection water pump pressurized delivery of injection aquatic water (about 1 2 barg);

The water supply pressure requirement is low (1 3 barg);

Raw material water can be softened water or single-stage reverse osmosis water;

Safety design (under the normal operating pressure, the high quality side pressure is greater than the low quality side pressure, and will not cause cross-contamination);

Low maintenance cost (for every 8000-9000 times, 2 bearings and their seals should be replaced. Total: 4 hours of maintenance every 2 to 3 years).

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Production Processing Equipment Category

Alkali recovery diffusion dialyzer

Price 1000.0 USD ($)

Minimum Order Quantity : 1

Drive Type : Other, Electric Motor

Automatic Grade : Other, Automatic

Water Source : Other, Industrial Effluent, Caustic Wastewater

Recycle Rate : up to 95%

Acid recovery diffusion dialyzer

Price 1000.0 USD ($)

Minimum Order Quantity : 1

Drive Type : Electric

Automatic Grade : Full Automatic

Water Source : Other

Recycle Rate : 90%95%

Homogeneous membrane electrodialyzer

Price 1000.0 USD ($)

Minimum Order Quantity : 1

Drive Type : Electric

Automatic Grade : Full Automatic

Water Source : Other

Recycle Rate : 90%95%

Nanofiltration system

Price 1000.0 USD ($)

Minimum Order Quantity : 1

Drive Type : Electric

Automatic Grade : Full Automatic

Water Source : Other

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Call Me Free

Call Me Free